Nicolas Abatzoglou

Université de Sherbrooke, Canada

Title: Techno-economic data and feasibility of hydrogen production from biogas using a novel low cost Ni-based reforming catalyst derived from metallurgical residues

Biography

Biography: Nicolas Abatzoglou

Abstract

Statement of the Problem: A new nickel catalyst was prepared from an ilmenite metallurgical residue consisting of an upgraded slag oxide (UGSO). Dry reforming of biogas, a mixture of equimolar amounts of CH4and CO2, does not necessitate other special reactants if the catalyst is effi cient and suffi ciently robust at the reaction conditions (T, P and gas spatial velocity). In recent scientifi c publications and a PCT patent pending, it has been shown that such a catalyst can be produced at low cost with a low-materials and energy intensity production protocol. Purpose: Present the preliminary engineering of an integrated industrialunit combining the in-house production of this novel catalytic formulations and its use to produce H2, using a typical landfi ll biogas or a combination of biogas and natural gas.

Methods:

Results: The study presents results on the following points:

• Description of the catalyst and its chemistry.

• Mechanistic aspects relying on fresh and used catalyst analyses.

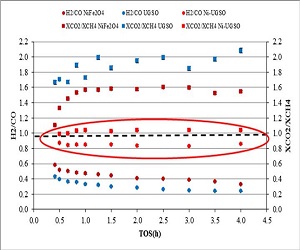

• Development of a phenomenological kinetic model, including the apparent activation energy of the controlling step and its use to simulate the reforming reactor operation.

• Proofs of the catalysts effi ciency, robustness, regenerability and an estimation of its life cycle.

• Description of this catalysts production unit aimed at both providing the necessary in-house quantities and tackle the external market.

• Preliminary engineering of a hydrogen production unit utilizing the new catalyst.

• Estimation of the production cost as function of the unit size in targeting to evaluate its break-even point.

Conclusion: The conclusion will focus on the techno-economic feasibility of such an industrial project within the actual

market globalization context as function of parameters such as, size, reactants and products market price, market outreach and socioeconomic and environmental incentives.