Rakesh Govind

University of Cincinnati, USA

Title: Systematic generation of reaction pathways for manufacturing bulk industrial chemicals from carbon- neutral feedstocks

Biography

Biography: Rakesh Govind

Abstract

Problem Statement: The objective of this work was to develop a systematic strategy for generating efficient, alternate reaction paths that could be used to manufacture the top 100 industrial chemicals, currently produced from crude oil, using renewable feed-stocks. All organic chemicals play a vital role in synthesis of polymers, solvents, food products and fi bers, manufacturing these chemicals from oil, coal or natural gas results in increasing carbon dioxide levels in the atmosphere, responsible for global climate change.

Aim: The aim of this study was to use the existing knowledge on the conversion of carbon-neutral feed-stocks, like biomass, wood, etc., to suitable precursor raw materials and the known industrial reaction paths, currently used for manufacturing the top 100 industrial organic chemicals, to systematically develop and evaluate alternate carbon-effi cient reaction paths.

Methodology: A matrix model is generated that consists of 96 biomass sources and 105 major industrial chemicals, in which each element shows either the amount of chemical (represented by the matrix column) that is produced from a unit amount of biomass or the amount of carbon that is present in the chemical, represented by the matrix column, divided by the amount of carbon in the

chemical, represented by the row of the matrix, i.e., fractional carbon economy for the conversion of the chemical in the row to the chemical, represented by the column. The fractional carbon economy was determined from a comprehensive listing of industrial reactions paths, which also gives the yields and effi ciencies of these industrial reaction paths, currently being practiced in the chemical industry.

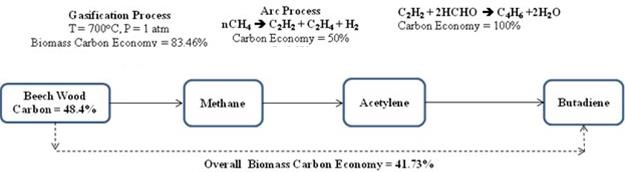

Result: Conclusion & Significance: This methodology allows a systematic generation of viable reaction paths for manufacturing industrial chemicals from renewable, carbon-neutral feed-stocks. An example of a chemical pathway generated by this methodology is shown in Figure 1.