Day 2 :

Keynote Forum

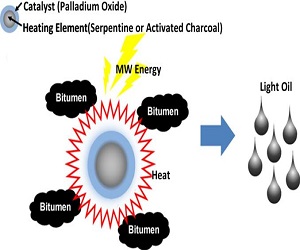

Adango Miadonye

Cape Breton University, Canada

Keynote: Microwave applications in petroleum processing

Time : 10:00-10:40

Biography:

Abstract:

Keynote Forum

Ramesh Agarwal

Washington University, USA

Keynote: Computational fl uid dynamics modeling and simulations of fl uidized beds for chemical looping combustion

Time : 11:00-11:40

Biography:

Abstract:

- Track 7: Chemical Polymer Technology

Track 9: Thermodynamics

Track 11: Environmental and Sustainable Chemical Engineering

Location: ZURICH

Chair

Ying Liu

University of Illinois, USA

Session Introduction

Igor Zhitomirsky

McMaster University, Canada

Title: Colloidal methods for the fabrication of advanced electrodes for electrochemical supercapacitors

Time : 11:40-12:10

Biography:

Abstract:

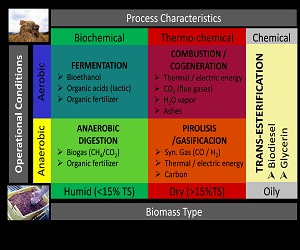

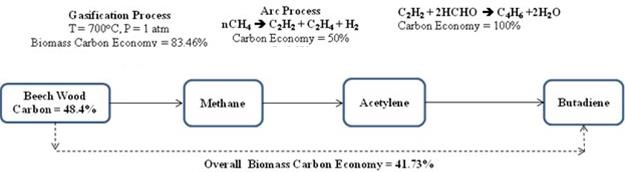

Daniela Almeida Streitwieser

Universidad San Francisco de Quito (USFQ), Ecuador

Title: The shift of raw materials from oil, coal and natural gas to biomass and residues

Time : 12:10-12:40

Biography:

Abstract:

Valentino Tiangco

Sacramento Municipal Utility District, USA

Title: Pre-and post-combustion NOx control system with hydrogen assistance and using microwave technology for biogas engines

Time : 12:40-13:10

Biography:

Abstract:

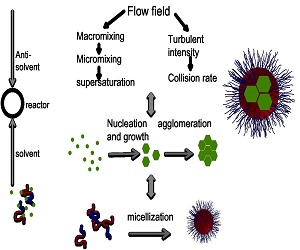

Ying Liu

University of Illinois, USA

Title: Polymeric nanoparticles encapsulating hydrophobic compounds for drug delivery

Time : 14:00-14:30

Biography:

Abstract:

Eri Yoshida

Toyohashi University of Technology, Japan

Title: Artifi cial biomembrane models using polymer giant vesicles: Morphological changes and enhanced permeability of the vesicles by incorporation of ionic segments into the polymer amphiphiles

Time : 14:30-15:00

Biography:

Abstract:

Rakesh Govind

University of Cincinnati, USA

Title: Systematic generation of reaction pathways for manufacturing bulk industrial chemicals from carbon- neutral feedstocks

Time : 15:00-15:30

Biography:

Abstract:

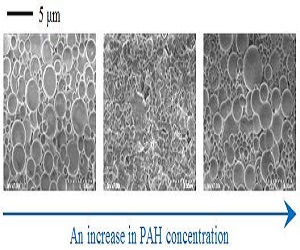

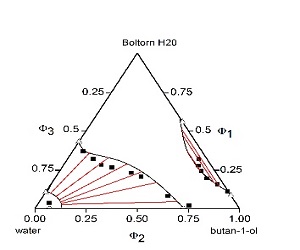

Sabine Enders

Karlsruher Institut für Technologie (KIT), Germany

Title: Polymer thermodynamics for pharmaceutical applications

Time : 15:30-16:00

Biography:

Abstract:

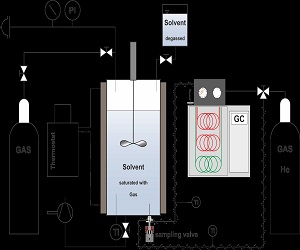

Kirsten Grubel

Ruhr-University Bochum, Germany

Title: Experimental solubility study on the high-pressure absorption of small molecules in ethanol oxidation reactions

Time : 16:20-16:40

Biography:

Abstract:

Poster Presentations 16:50-17-10.

Day 2 Program Closed By 17-10.